Author Archives: Norman Pirollo

Furniture Design Course

The Furniture Design Course teaches you furniture design and furniture making skills. The course is based on skills developed and used in a fully functioning furniture making studio. Learn from an expert in woodworking and furniture making. Norman Pirollo, a woodworker and furniture maker for over 25 years, has had his work published in several magazines and books. In this period, he has established four woodworking businesses. Norman has also written the From Hi-Tech to Lo-Tech: A Woodworker’s Journey book, chronicling his journey into woodworking. He recently authored the Woodworking: From Design To Making book.

In this course, I cover furniture design. Good design is essential in a quality furniture piece. Good design minimizes wasted resources and provides a furniture maker with essential feedback and pause when creating furniture. Loosely translated, the design process keeps a maker from rushing into a potentially flawed furniture design. The checks and balances give pause to the process as well as streamlining the build. Developing your own furniture style and aesthetic is covered. Selecting the right woods for a furniture design is critical in determining the appeal of a furniture piece.

As with most woodworkers, I was anxious to build furniture early on. With the passage of time and several furniture project completed, the anxiety of simply creating work had passed. It was far more important to create a well-designed and striking piece of furniture. So I delved into furniture design, studied with a few renown furniture makers, and used this knowledge to develop a furniture design process that works.

In the online furniture design course you will acquire skills necessary to design and create your own unique furniture. Learn to develop your own style of furniture and aesthetic. Over 3 hours in total. The course features videos on these topics:

In the online furniture design course you will acquire skills necessary to design and create your own unique furniture. Learn to develop your own style of furniture and aesthetic. Over 3 hours in total. The course features videos on these topics:

- Furniture design overview, history of furniture design

- Become familiar with furniture design process

- Understand design, bring your furniture designs to next level

- How to select wood for a furniture design

- Use mockups + prototypes to develop furniture designs

- Selecting a furniture style and aesthetic

- Developing a furniture design

- Getting proportions right in furniture design

- Use dynamic design process in furniture design

- Use maquettes + prototypes in furniture design

- Use templates + CAD to design your furniture

- (2) video lectures on creating a niche & developing furniture to market

– Separate Introduction module

– 15 video modules from wood selection, drawing, mockups, prototypes, CAD

– Modules can be followed in any order and stopped or repeated at any time

– 15 video modules (3+ hours) included in the single $40 price

START WOODWORKING (eBook, 115 pgs., $15) included with this course

Norman maintains a blog of ongoing projects in his studio at: Pirollo Design Blog as well as having written and published six books in recent years. Some books and magazines where authors furniture, work methods and philosophy have been featured:

Quiet Woodworking (New Art Press)

Hand Tool Woodworking (New Art Press)

Start Woodworking (New Art Press)

Craftisian Interview (Norman Pirollo)

HackSpace Magazine – Make With Wood April 2020

Woodworking: From Design To Making (New Art Press)

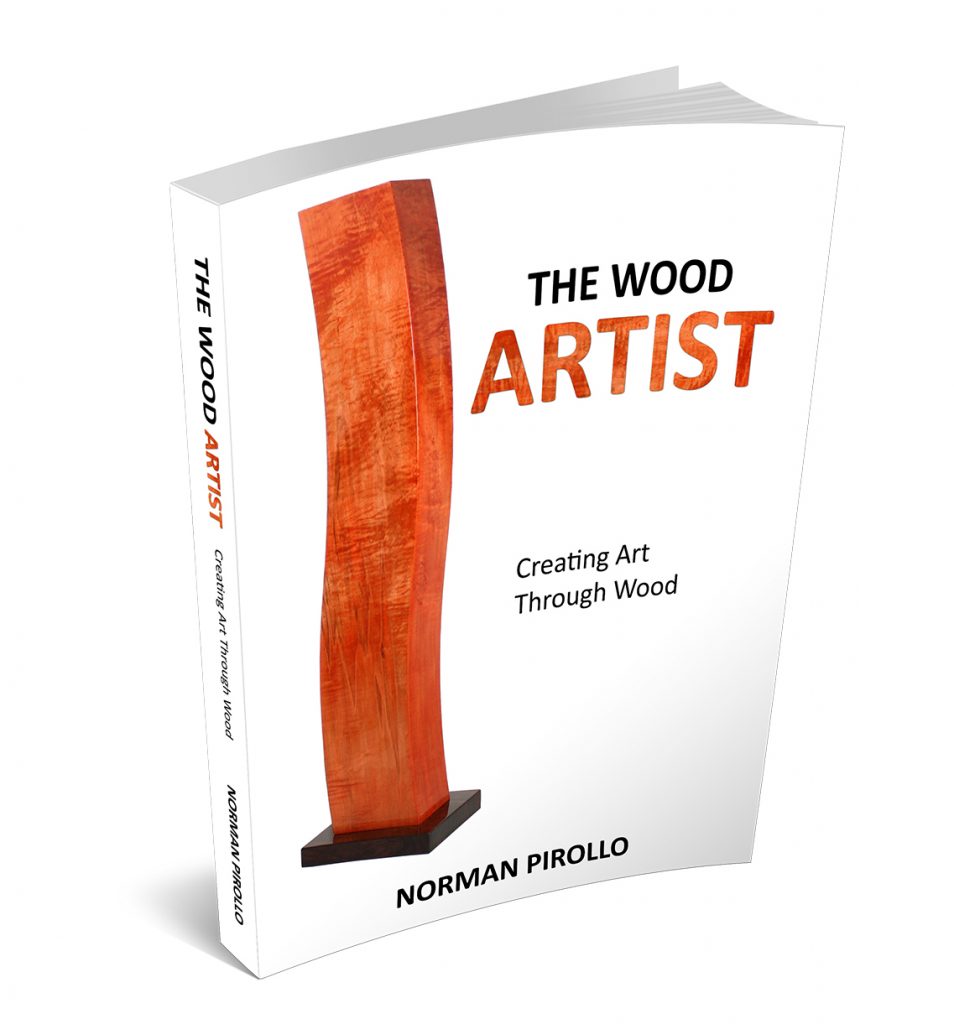

The Wood Artist: Creating Art Through Wood (New Art Press)

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (NAP)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer)

IDS15 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014

IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking Magazine – 4 Bench Jigs for Handplanes

Fine Woodworking Magazine – Essential Shopmade Jigs

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer)

Canadian Interiors Design Source Guide

Ottawa Life magazine (Profile,work) 2012

Panoram Italia magazine

Our Homes magazine

Craft Journal

The evolution…

Several years ago, 2006 to be exact, Michael Dresdner contacted me to ask about profiling my work and practice in an upcoming Woodworker’s Journal online publication. Of course, I jumped at the opportunity to talk about my woodworking and how I got to where I was at the time. I was transitioning from primarily being a box maker to furniture making and the reasons for this shift in direction were discussed in the interview.

In that period, I had completed a series of courses at a high-end furniture making school and began to use hand tools more in my work. I recall that the year 2006 was an important juncture in my woodworking. I had embraced the Krenov philosophy and his methods of work. Reading and attending the fine furniture making school inspired me to increase the complexity and scale of my woodworking. I also learned to slow down my woodworking and focus instead on each and every piece rather than applying myself to creating in batch mode ( multiples). So my direction changed dramatically in the years 2006-2008 to where I now design + build one-off furniture pieces exclusively.

In that period, I had completed a series of courses at a high-end furniture making school and began to use hand tools more in my work. I recall that the year 2006 was an important juncture in my woodworking. I had embraced the Krenov philosophy and his methods of work. Reading and attending the fine furniture making school inspired me to increase the complexity and scale of my woodworking. I also learned to slow down my woodworking and focus instead on each and every piece rather than applying myself to creating in batch mode ( multiples). So my direction changed dramatically in the years 2006-2008 to where I now design + build one-off furniture pieces exclusively.

The most important takeaway from the interview would likely be the last line: “If you are tired of your day job, Pirollo advises, do what I did. Pursue your passion instead.” I completely believe in this quote to this day. It is never to early to pursue your passion. Get a head start, so if unforeseen circumstances affect your livelihood (career), you will be prepared. Early on my hi-tech career, I pursued many woodworking courses at the college level, set up my own workshops and struggled and worked at learning woodworking. After experiencing a total of 3 downsizings, I gave up on my hi-tech career and moved on to a career in woodworking. This had been my Plan B all along 🙂 The important part is that I was well prepared to launch a second career. You never know where fate will lead you!

I’ll let you read the article.

Norman Pirollo: The Refined Edge of White Mountain

Hand Tool Class

– over 4.4 hours with extra $28 in plans

– 29 video lessons from workshop basics to critical hand tools skills

– lessons are followed in any order and stopped + repeated any time

– all lessons are included in single price

– printable reference material included

– Dovetail Jig Plan + Tutorial ($14 value) included in purchase

– Shooting Board Plan + Tutorial ($14 value) included in purchase

– Bench Hook project included

The video lessons include step by step hand tool sequences. Each lesson guides you through the learning process to develop the hand tool skills you are seeking. This Hand Tool Class is derived from twenty years of woodworking and furniture making expertise. The class is based on skills developed and used in a fully functioning furniture making studio. The class features separate modules on the following topics:

– setting up a workshop for woodworking

– up to date info on workshop safety

– hand tool overview

– lessons on handplanes and chisels

– lessons on clamps, handsaws

– lessons on marking tools

– dovetail jig + shooting board plan $28

– make handmade dovetails using jig

– dovetail class

– learn to make + use a shooting board

– learn to make + use bench hooks

– Bench Hook project included

– intro to Moxon Vise

– Thicknessing Sled (workbench jig)

– workbench sequences

– Knife Hinge Install

– hand tool class will get you going with hand tools

29 video lessons included with purchase of Hand Tool Class. 29 HD Video modules + Dovetail Jig Plan + Shooting Board Plan for $40

Norman maintains a blog of ongoing projects in his studio at Pirollo Design Blog as well as having written and published four books in the past year. Some of the books and magazines where authors furniture, work methods and philosophy have been featured:

Quiet Woodworking (New Art Press)

Hand Tool Woodworking (New Art Press)

Start Woodworking (New Art Press)

Craftisian Interview (Norman Pirollo)

HackSpace Magazine – Make With Wood April 2020

Woodworking: From Design To Making (New Art Press)

The Wood Artist: Creating Art Through Wood (New Art Press)

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (NAP)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer)

IDS15 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014

IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking Magazine 4 Bench Jigs for Handplanes

Fine Woodworking Magazine Essential Shopmade Jigs

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer)

Canadian Interiors Design Source Guide

Ottawa Life magazine (Profile,work) 2012

Panoram Italia magazine

Our Homes magazine

Course Overview (short, lo-res) below.

Cabinet Build Class

I have recently compiled a series of 16 videos into an online class. The subject was a recent display cabinet. The design and build of the striking Krenov-inspired display cabinet seen above is discussed and demonstrated. The contemporary styled display cabinet features veneered sides and doors. The veneers selected are highly figured although they can be substituted with alternative veneers. The frame and panel back adheres to the Krenov principle of properly finishing the back of the cabinet. James Krenov is widely known for his classic cabinets on stand as well as the incredible attention to detail he brought to furniture making. He also brought a unique philosophy and vision to furniture making of which I heed and practice. A large part of this veneered display cabinet has been created using an assortment of hand tools although some machinery is used in the initial wood preparation stage. Follow me as I describe the steps involved in creating a masterpiece veneered cabinet on stand.

The following topics are covered in detail in this 16 part design and build class:

The following topics are covered in detail in this 16 part design and build class:

- Inspiration and design of the display cabinet

- An overview discussing components of the cabinet

- Wood selection and resawing veneers used in cabinet

- The advantages of using veneers over solid wood

- Detailed information on creating and using resawn veneers

- The process of applying veneers to the sides and doors

- Implementing bake-ins to create panels with hardwood edges

- Hardwood edging and the veneer press

- The veneer press and joinery used in the cabinet

- Card scrapers and the use of a shop-made drilling guide

- Dowel drilling guide in-depth

- The case construction process

- Frame and panel construction of the back panel

- Back panel detail and installation

- Final case assembly of the display cabinet

- Installation process of knife hinges for the doors

Each video segment addresses one aspect of the cabinet build. The design process as well as the methodology behind the build are addresses. This is not simply a class on how to build a cabinet on stand. The class will inform you of a similar design process that James Krenov used in his own work. Since I am an ardent follower of James Krenov, the practices I use in this cabinet build closely follow those of James Krenov. Discussions and demonstrations describe how the design of this display cabinet originated and the design considerations in its build. Information on wood selection and preparation as well as the joinery used in this cabinet is covered in detail. Tips and techniques acquired over several years of creating this style of cabinet are shared in this class. The process of creating and applying veneers is covered as well as information on the installation of knife hinges. More info in the Tutorials section.

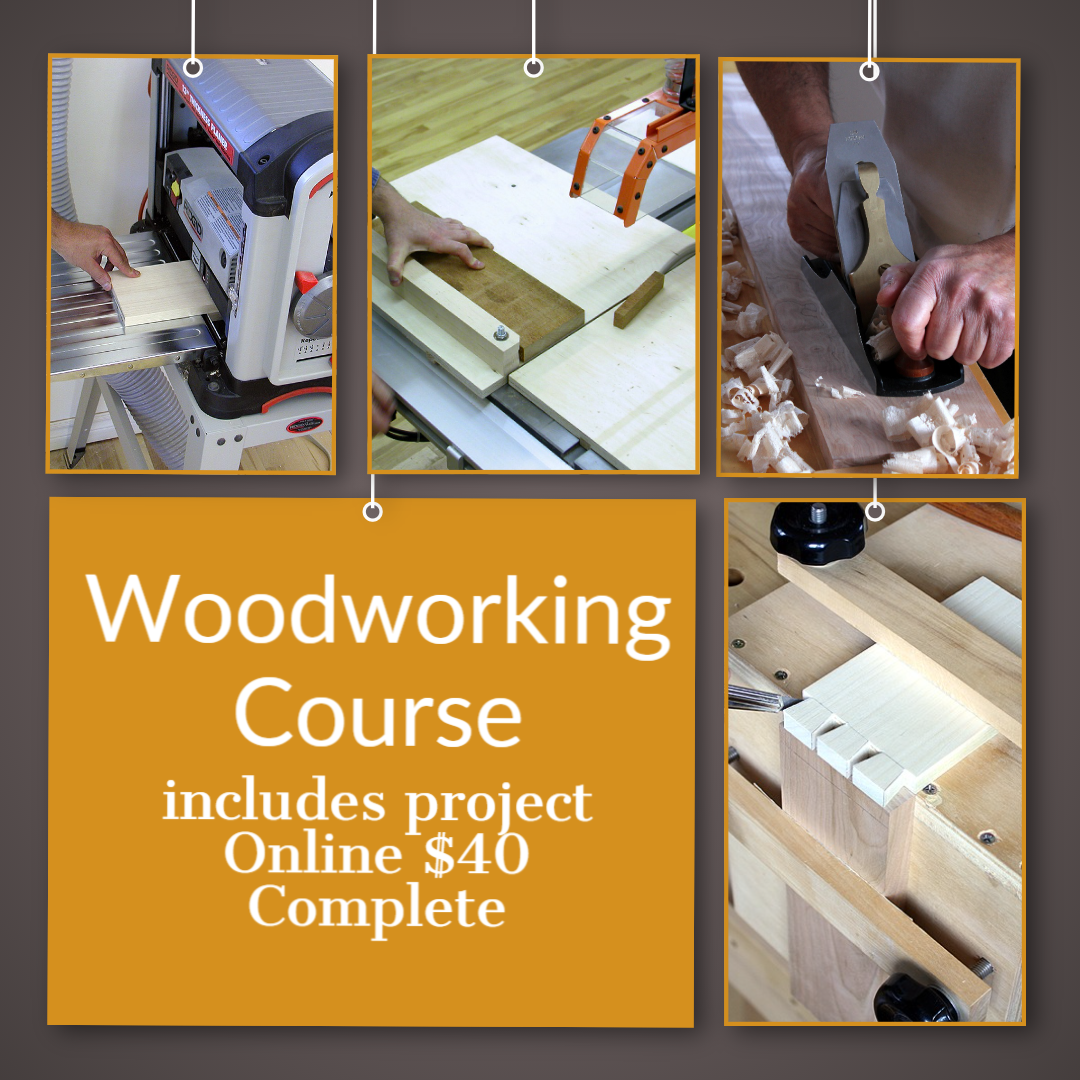

Woodworking Course

The WoodSkills Woodworking Course will dramatically improve your woodworking and furniture making skills. The course is based on skills developed and used in a fully functioning furniture making studio. Learn from an expert in woodworking. Norman Pirollo has been woodworking for over 25 years, his work published in magazines and books and established four woodworking businesses. Norman has also written and published the From Hi-Tech to Lo-Tech: A Woodworker’s Journey book, chronicling his exciting journey into woodworking. Most recently, Norman has authored the Woodworking: From Design To Making book.

The woodworking course features separate modules on these topics:

– how to select and prepare wood

– how to design and set up a workshop

– up to date information on workshop safety

– modules on hand tools and power tools

– learn joints and how to create them

– learn to make handmade dovetails

– learn mortising with hand and power tools

– working in a hybrid environment of hand and power tools

– how to use a jointer, planer, router, tablesaw, bandsaw

– choosing + applying finishes

– intro to veneering with veneering basics

– intro to bench hooks

– bench hook project included

– intro to the shooting board

– intro to Moxon Vise

– dovetail class

– workbench sequences

– over 6 hours in total

– 41 video modules (wood selection, tools, joinery, veneering, finishing)

– modules can be followed in any order and stopped or repeated

– 41 modules included in single $40 price

– printable reference material included for each module

– Woodworking Fundamentals Certificate available upon completion

The video modules include step by step woodworking sequences. Each module guides you through the learning process to develop the skills you are seeking. The Woodworking Course is derived from 25 years of woodworking expertise.

START WOODWORKING (eBook, 115 pgs., $15) included with this course

Jorge R. Perez of Flushing , NY says this about Woodworking Course

“It helped me improve my woodworking skills considerably ”

Steve Vidal of Throop, Pennsylvania says this about Woodworking Course

“All woodworkers, novice or professional, will benefit from this course “

Bruce Holden of Cut Knife High School, Saskatchewan says

“Congratulations on an excellent woodworking course! I teach woodworking in a rural Saskatchewan high school and recommend your course to my students.”

James Cowell of Glendale, Utah says this about Woodworking Course

“I wanted to learn woodworking but didn’t know where to begin. The course helped me out”

Purchase Woodworking Course course with 41 HD Video lectures for $40

Norman maintains a blog of ongoing projects in his studio: Pirollo Design Blog as well as having written and published six books in recent years. Books, magazines where authors furniture, work methods and philosophy have been featured:

Quiet Woodworking (New Art Press)

Hand Tool Woodworking (New Art Press)

Start Woodworking (New Art Press)

Craftisian Interview (Norman Pirollo)

HackSpace Magazine – Make With Wood April 2020

Woodworking: From Design To Making (New Art Press)

The Wood Artist: Creating Art Through Wood (New Art Press)

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (NAP)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer Publishing)

IDS15 (Studio North)

IDS14 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014

IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking Magazine – 4 Bench Jigs for Handplanes

Fine Woodworking Magazine – Essential Shopmade Jigs

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer)

Canadian Interiors Design Source Guide

Ottawa Life magazine (Profile,work) 2012

Panoram Italia magazine

Our Homes magazine

Craft Journal

Furniture Design Course

In this new course, I cover the furniture design topic. Good design is essential in a quality furniture piece. Good design also minimizes wasted resources and provides a furniture maker with essential feedback and pause when creating furniture. Loosely translated, the design process keeps the maker from rushing into a potentially flawed furniture design. The checks and balances give pause to the process as well as streamlining the build. Developing your own furniture style and aesthetic is covered. Selecting the right woods for a furniture design is critical in determining the appeal of a furniture piece.

As with most woodworkers, I was anxious to build furniture early on. With the passage of time and several furniture project completed, the anxiety of simply creating work had passed. It was far more important to create a well-designed and striking piece of furniture. So I delved into furniture design, studied with a few renown furniture makers. and used this knowledge to establish a furniture design process that works.

With the limited time we have available today, it becomes critical to use it productively and efficiently. Developing a good furniture design saves time and resources and provides a more rewarding furniture build. Getting the proportions right is also essential in establishing the appeal of the furniture piece. So I am passing on my knowledge of furniture design in this new course and hopefully establish a dialog of furniture design with participants in the course.

With the limited time we have available today, it becomes critical to use it productively and efficiently. Developing a good furniture design saves time and resources and provides a more rewarding furniture build. Getting the proportions right is also essential in establishing the appeal of the furniture piece. So I am passing on my knowledge of furniture design in this new course and hopefully establish a dialog of furniture design with participants in the course.

The Wood Artist: Creating Art Through Wood

Norman Pirollo, wood artist at Pirollo Design, describes his exciting transition from furniture designer + maker to wood artist. The journey involved philosophical decisions about which type of work quenched his creative urges. The shift in direction also involved alternating between purely functional to non-functional, decorative work. Norman reveals how he transformed his designs from purely functional furniture to non-functional wood art where form is preeminent.

Norman also recounts his fifteen year creative journey where he would strive to seek creative outlets. Working as a multidisciplinary artist ultimately became his vocation. Follow the riveting story of how a furniture designer + maker evolved into a multidisciplinary artist including contemporary furniture, sculpture, wood art and photo art. The video below is a retrospective of some of his recent work. The evolution includes the introduction of curved elements and colored wood at different junctures.

Read how Norman, through determination and perseverance, finally attained his goal of becoming a wood artist. Delving into and studying art history has provided him the art language and background to develop his own art vision. Discover how he immersed himself into the contemporary art movement to develop a style and voice of his own. Find out how, through twists and turns, Norman acquired the skills and techniques to become an award-winning wood artist. The opportunity to work at something he truly enjoys has ultimately brought him solace and independence.

Norman maintains a blog of ongoing projects in his studio at: pirollodesign.com as well as having recently written and published four books. Books and magazines featuring the authors furniture, work methods and philosophy:

Norman maintains a blog of ongoing projects in his studio at: pirollodesign.com as well as having recently written and published four books. Books and magazines featuring the authors furniture, work methods and philosophy:

The Wood Artist: Creating Art Through Wood (New Art Press)

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (New Art Press)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer Publishing)

IDS15 (Studio North)

IDS14 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014 IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking magazine

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer Books)

Fine Woodworking Shopmade Jigs 2009 2012

Canadian Interiors Design Source Guide

Ottawa Life magazine

Panoram Italia magazine

Our Homes magazine

Craft Journal

215 Pages, Non-fiction, Softcover.

Digital version available ($15) at WoodSkills

Print version of book $19 available directly through Amazon

The Wood Artist: Art Thru Wood

I’ve been working at writing a book on an off these past few months. Only recently has the final title been decided on: The Wood Artist: Creating Art Through Wood. The book chronicles the evolution of my wood art and sculpture over several years. Several discoveries about wood are noted. I am excited about this book as this particular subject is part of the continuum of my second career as a furniture maker and wood artist. A few years ago, I never would have envisioned being part of the art world. It is through the medium of wood that I stumbled into it. One thing led to another and soon I developed a sufficient body of work to make serious inroads into the art world. Shifting from creating functional furniture to creating purely non-functional, non-objective art was challenging at times. At the same time, the creation of art unleashed a newfound creativity and vision that could not be manifested through my furniture designs.

This is more than simply a picture book. In it I discuss the methodology and processes I developed to be able to create small and large pieces of wood art. As well, discoveries about the inherent characteristics and beauty of wood are discussed. Both sculptural and wall art are part of the journey. The wood art and sculpture closely follow the genre of contemporary art. It has been an exciting period in my career as both a woodworker and wood artist. I continue to work at both today. The book is 215 pgs. in total. So I created the video below as a retrospective of some of my recent work. The evolution includes the introduction of curved elements and colored wood at different points. Currently it is in the final stage of completion. The final version is being printed at this time. The book is targeted for publication on October 11, 2017.

Can be now be ordered through Amazon. Information on ordering also at www.refinededge.com/books

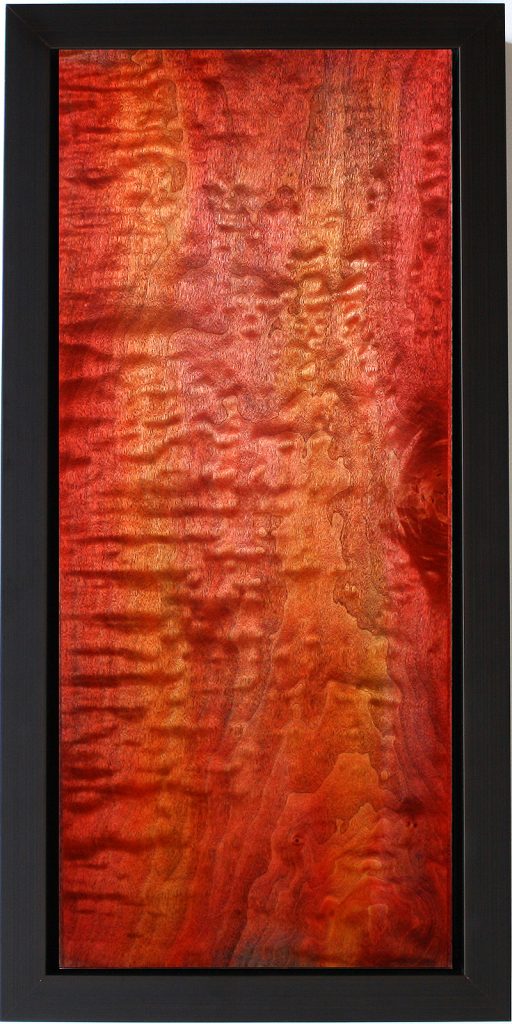

Spectrum

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

24 in. H, 12 in. W, 2.75 in. D

Inferno

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a raging inferno and is composed of a combination of highly figured maple, clear maple and a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a raging inferno and is composed of a combination of highly figured maple, clear maple and a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Eternal Flame

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Slice Of Nature

Uniquely designed sculpture in a three dimensional modern style. This upper part of the sculpture is a tapered pie-shaped cross-section of an African blackwood tree which includes the lighter live edge or bark portion. The base of the sculpture is sliced from a mesquite tree. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac.

Uniquely designed sculpture in a three dimensional modern style. This upper part of the sculpture is a tapered pie-shaped cross-section of an African blackwood tree which includes the lighter live edge or bark portion. The base of the sculpture is sliced from a mesquite tree. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac.

12.5 in. H, 5.5 in. W, 5.25 in. D

Genesis

Uniquely designed sculpture in a three dimensional modern style. This sculpture is a cross-section; of an African blackwood tree which includes the lighter live edge or bark portion. The natural organic shape of the sculpture displays the beauty which nature has provided us. The base of the sculpture is sliced from a mesquite tree and outlines the natural growth rings which have accumulated over time. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac and polished.

Uniquely designed sculpture in a three dimensional modern style. This sculpture is a cross-section; of an African blackwood tree which includes the lighter live edge or bark portion. The natural organic shape of the sculpture displays the beauty which nature has provided us. The base of the sculpture is sliced from a mesquite tree and outlines the natural growth rings which have accumulated over time. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac and polished.

12 in. H, 13 in. W, 5.5 in. D

Reverence

Uniquely designed mixed media sculpture in an art deco style. Angular cherry sides combine both stepped form and chevron design elements. The triangle shaped center has a blackwood inlay. This combination of art deco style elements symbolizes a cupping or holding in reverence of the center component. Metal serves to join the center piece to the sides. The base is solid blackwood. Surfaces are hand scraped and formed. Meticulous attention is provided to both detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac, polished and waxed.

Uniquely designed mixed media sculpture in an art deco style. Angular cherry sides combine both stepped form and chevron design elements. The triangle shaped center has a blackwood inlay. This combination of art deco style elements symbolizes a cupping or holding in reverence of the center component. Metal serves to join the center piece to the sides. The base is solid blackwood. Surfaces are hand scraped and formed. Meticulous attention is provided to both detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac, polished and waxed.

11 in. H, 15 in. W, 3.25 in. D

Shrine

Uniquely designed sculpture in a three dimensional modern style. This sculpture depicts a shrine and is composed of a combination of big leaf maple, ebony, stone and blackwood. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac.

Uniquely designed sculpture in a three dimensional modern style. This sculpture depicts a shrine and is composed of a combination of big leaf maple, ebony, stone and blackwood. Meticulous attention is provided to detail and finishing. The wood is not stained and attains a natural patina over time and with exposure to ambient light. Finished with multiple coats of thinned shellac.

9 in.. H, 11 in. W, 4 in. D

Interrupted

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

17 in. H, 7.5 in. W, 3.25 in. D

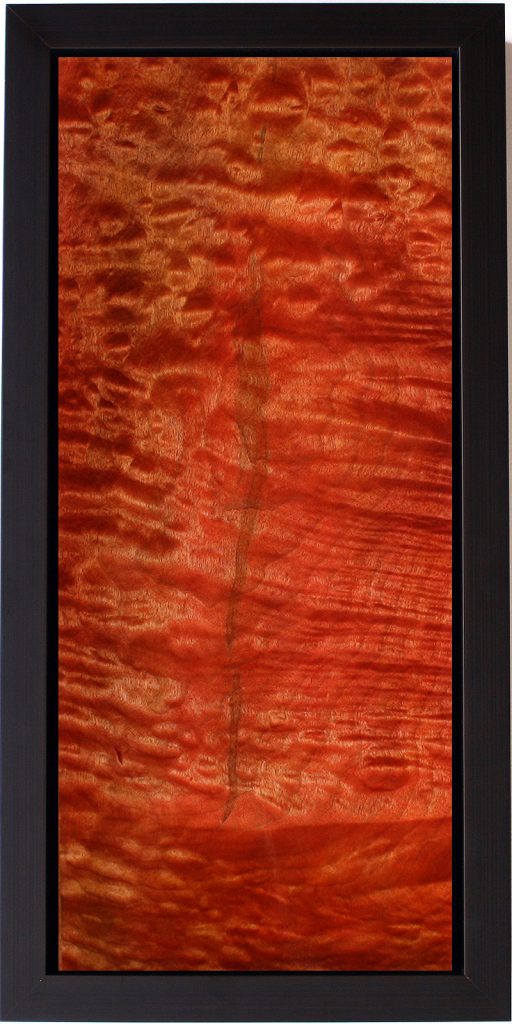

Sundown

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Spring Bulrush

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured maple evokes a unique depiction. The wall art is raised and set in a platinum frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured maple evokes a unique depiction. The wall art is raised and set in a platinum frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

29 in. H, 14 in. W, 2.25 in. D

Inferno III

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Celestial

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Disturbance

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

Uniquely designed wall art in a three dimensional contemporary styling. Highly figured quilted maple evokes a unique depiction. The wall art is raised and set in a black frame to provide three dimensionality and depth. All surfaces are hand planed and scraped to provide meticulous attention to both detail and finishing. Finishing performed utilizing a classic French Polishing technique.

24 in. H, 12 in. W, 2.75 in. D

On Fire 1

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple veneers with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple veneers with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

38 in. H, 10 in. W, 8 in. D

On Fire

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple veneers with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

Uniquely designed sculpture in a three dimensional contemporary style. This organic sculpture depicts a rising flame and is composed of highly figured maple veneers with a rosewood base. Meticulous attention is provided to detail and finishing. Finished with multiple coats of thinned shellac in a French Polish process. This process maintains the clarity and depth of the figured woods and draws out the natural undulating graphics.

1860’s Sawmill, Cabinet shop

This past week while camping I toured an authentic 1860’s pioneer village in the area. We camp in the same area each year and try to visit Upper Canada Village while there. With each visit I learn something new or pick out a detail I missed on previous visits. One favorite stop is the authentic sawmill which continues to produce boards to this day. Most of the wood is used within the village. Watching the water-powered bandsaw in operation continues to amaze me. The innovative features built-in to process logs into boards are nothing short of ingenious. There is also a system to use trucks on wheels to transport logs in , then roll them onto the bandsaw platform for ripping. The videos below shows the bandsaw in operation and water turbine at the lower level. Blade is stationary except for up and down movement. The log is advanced into the blade through a system of geared steel wheels and detents. The bandsaw is powered by a shaft driven by a turbine wheel. The water is piped in to the sawmill through a system of square wood pipes which increase the velocity of water to spin the turbine. Water begins at one height when entering the sawmill and exits at a lower level. This is what causes the water to increase in velocity. The bandsaw mill works well with old growth white pine brought in from another area.

Video here: Water-Turbine

Video here: Water-powered 1860 bandsaw

Another favorite stop is the authentic cabinetmaker shop where furniture is continually churned out, albeit at a much slower pace we are familiar with. Most of the furniture produced in the shop is used in the authentic pioneers village. All furniture is created with hand tools as relatively no woodworking machines existed in this era. The Industrial Age was just beginning. Watching the cabinetmaker (David Jones) and apprentice provided a real appreciation for a slower, manual form of woodworking.

So I had the opportunity to do a short film of David Jones (resident master cabinetmaker) and apprentice. I asked a few questions while filming. They are currently working on a side table with frame and panel doors and drawers. All joinery is either pinned mortise and tenon or dovetails.

I have probably visited this Cabinetmakers shop four times to date and continue to enjoy discussing with the resident cabinetmakers their work methods and current projects.

Video here: 1860 Cabinetmaker Shop

I then visited the blacksmith shop which also doubles as the ferrier shop for the horses in the village. Had a good talk with the blacksmith. At the time he was forging a keyway for a geared wheel in a piece of machinery used in the crop fields of the village.

slider25

Bench stops (12th anniversary)

In 2005, I developed this system of bench stops as a simple alternative to installing a tail vise on a workbench. So I’ve been using this system of bench stops for 12 years now, it will be the 12th anniversary shortly! The system is set up on one of my original workbenches which happened to be my main workbench at the time. This particular shop-made workbench did not lend itself well to incorporating a tail vise so I told myself there had to be a better way to hold boards firmly while hand planing. Apologies for the vintage photography, but I wanted to keep the article period correct 🙂

This alternative tail-vise setup is used when face planing boards. Most flat, regular benches can easily be modified to incorporate this hand planing setup using bench stops ( Roubo style). Photos below are of the bench stop setup on the workbench in my workshop. This bench has been modified for adapting the two bench stops. Adapting a bench can be expanded for longer bench stops, more holes for versatility, etc. I chose this particular hole spacing for the type of work I do. I am also left-handed and plane left to right, therefore I set this up on the back side of my bench which is unencumbered by a face vise ( the face vise at front of bench ).

It is critical to get the 3/4 in. dowel holes square to the bench and in-line with each other, to ensure that the 12 in. bench stops are perpendicular to each other. The side bench stop does a great job of preventing the board from rotating sideways while hand planing with diagonal strokes. It has a large bearing surface to keep any size board from rotating. The side bench stop is also movable within a 12 in. span on 3 sets of holes, allowing for narrow boards and wider boards (2 in. to 14 in.).

The side bench stop can be swung around towards the front bench stop with a parallel set of holes, this is to accommodate shorter boards. Pictures above and below provide a better explanation.

The wide front bench stop also serves to prevent the board from rotating or shifting sideways as it has a large bearing surface for the front edge of the board. Bench stops (front and side) are friction fit so they can be raised (1/4 in. to 3/4 in.) to accommodate thicker boards, very much like a bench dog. Otherwise, the minimum height of the bench stops would be approximately 1/4 inch. The hole spacing is arbitrary and based on the type of board sizes I typically hand plane in my own furniture making. two inch long birch dowels are glued in the bench stops using ebony wedges. The wedges are inserted into kerfs created in the ends of the dowels for tightness. Kerfs at the ends of the dowels are cut on a bandsaw.

A benefit of having a board simply against bench stops is that you really cannot drag the plane back in your strokes since it would pull the board back. This trains you to lift the handplane instead of dragging it back. The only wear on the blade then is from the forward stroke. Also you eliminate the tendency of bowing a thinner board caused by clamping between bench dogs and tail-vise and distorting the board while planing. You also gain more tactile feedback and control of your planing and it becomes easy and quick to re-orientate the board end for end or flip it over, etc.

Typical bench stop setup to act as a tail vise.

More holes can be added to allow for very short boards as done in bottom pictures. It is then a matter of swinging the side bench stop around towards the front bench stop. The spacing and location I have selected is optimized for the length and width of boards I typically handplane in my furniture making.

The bored 3/4 in. holes can also be used for bench dogs and holdfasts for irregular sized pieces.

Align side bench stop to be perpendicular with face of front bench stop using a large square to mark holes. This will ensure the complete edge of the bench stop is against the board to be planed.

Side bench stop set to narrowest width, closest to edge of bench.

Bench stops can be raised or lowered as conventional bench stops for thinner or thicker boards.

A short, narrow piece of lacewood being planed.

Parallel set of holes bored to accommodate shorter and wider boards shown above. It is recommended to lay out all the holes you will need for this system and then drill them. This ensures that all holes are square and perpendicular to each other and the front bench stop.

A small, wide panel being face-planed.

Developing this alternative tail vise idea led to an article on bench stops and jigs I wrote for Fine Woodworking Magazine. The article 4 Bench Jigs for Handplanes was published in early 2009.

Furniture maker’s mark…

The concept of a maker’s mark is not a new one. It has been around for centuries. It is a means to distinguish one’s work from another maker. It also adds a personal touch to every piece created by a maker. I have incorporated maker’s marks in my own work for the past two decades and have had excellent feedback from clients. Clients love the fact that the furniture piece they purchase is created by an individual. It adds to the cachet of the piece and serves to provide identification of the origin of the piece. Decades from now, the maker’s mark instantly identifies the furniture piece as created by a particular maker with the location of its creation. The new maker’s mark designed for my studio captures the essence of my work and the detail I like to instill in my work.

So I also use the new maker’s mark for my other work, namely woodworking tools. I find a place on each tool to inlay the maker’s mark. In a strange way, adding a maker’s mark inspires me to do my best work. Attaching my name to a furniture piece or handmade tool makes me more conscious of how the tool or furniture will likely be passed on from generation to generation.

So I also use the new maker’s mark for my other work, namely woodworking tools. I find a place on each tool to inlay the maker’s mark. In a strange way, adding a maker’s mark inspires me to do my best work. Attaching my name to a furniture piece or handmade tool makes me more conscious of how the tool or furniture will likely be passed on from generation to generation.

Furniture maker’s marks also provide a historical point of reference to a piece of furniture or tool. The maker and country of origin can then be traced back to a particular maker. Maker’s marks can be stamped on a furniture piece or hand tool or created as brass inlay similar to this new one applied to my work.

Furniture maker’s marks also provide a historical point of reference to a piece of furniture or tool. The maker and country of origin can then be traced back to a particular maker. Maker’s marks can be stamped on a furniture piece or hand tool or created as brass inlay similar to this new one applied to my work.

I hope everyone is enjoying the summer. It is my favourite time of year. I can shed the layers of clothing of other seasons and simply walk out the door. No complaints here about heat or humidity. This only really lasts a few weeks or months and the freezing cold alternative is always fresh on my mind 🙂

I hope everyone is enjoying the summer. It is my favourite time of year. I can shed the layers of clothing of other seasons and simply walk out the door. No complaints here about heat or humidity. This only really lasts a few weeks or months and the freezing cold alternative is always fresh on my mind 🙂

slider28

Miter saw stand…

A while ago, I realized that my workflow would be more efficient if I had the means to cut long planks into manageable pieces. Longer planks ensure that wood graphics are consistent in the woods used in a particular furniture piece. The shorter pieces would, in turn, be processed on a jointer and thickness planer. In the case of highly figured tearout-prone woods, I would use a series of hand planes to achieve the desired board thickness.Until this time, I would crosscut large planks using a hand-held circular saw. If any precision was necessary at all, the circular saw left something to be desired. So enter the miter saw. I purchased a sliding miter saw and designed and built a stand for it. The criteria for the stand were that it be portable so I could move it around the shop if necessary. It was also important that it be designed to be folded up after use and placed along a wall. The intention was to have the miter saw available occasionally for cutting large planks down to size. I only ever work with one or two planks for a particular piece of furniture, so the miter saw could be put away between use. A few wide boards I use in my furniture can be seen against the wall at left.

I designed and built this miter stand for my particular miter saw, a Dewalt 10 in. model. The miter saw itself can easily be detached from the stand and the table surface folded onto the metal sawhorses below. Since this would be a custom build, I could make the miter stand as long as I like. I decided on a length of over 7 feet. The left and right tables each have a fence system aligned with the miter saw fence. The largest width of planks I could process is approximately 10 inches. This is as wide as most, if not all of the planks I ever use in my work. Anything wider I can either rip an edge off or find alternative means to cross-cut it.

Each fence has its own track system with both shop-made wood stops and retail metal stops. I uses the torsion box principle to build the left and right tables. Even with the utmost design in mind, it was necessary to make changes. When wide miter cuts were necessary on large wood pieces, it would be convenient to use the miter saw. This hold more true if the cuts are repeatable as when working with multiples. Swinging the saw completely to the left or right was an issue. Hence the re-designed mitered corners in both the left and right tables. I can set the saw to extreme miter angles now, greater than I would normally use in my work. So after replacing the corner of either table with hardwood cherry blocks and trimming, the mitered corners can be seen below.

I have been using this miter saw and stand setup for a long while now. I never did fold and put it away. It is so convenient that I prefer it to remain set up. Soon after using it for the first few times, I realized dust control would be necessary. A dust port adapter was set up to connect the exhaust port to a dedicated shop vacuum. Still debating whether I need to make a dust shroud for it, but it works well as is and I like that the miter saw isn’t hidden in a shroud. Overall, a fun, exciting build and at times challenging!

I have been using this miter saw and stand setup for a long while now. I never did fold and put it away. It is so convenient that I prefer it to remain set up. Soon after using it for the first few times, I realized dust control would be necessary. A dust port adapter was set up to connect the exhaust port to a dedicated shop vacuum. Still debating whether I need to make a dust shroud for it, but it works well as is and I like that the miter saw isn’t hidden in a shroud. Overall, a fun, exciting build and at times challenging!

From Hi-Tech to Lo-Tech: A Woodworker’s Journey

Norman Pirollo, successful founder of White Mountain Design, White Mountain Toolworks, WoodSkills, Refined Edge Design and Pirollo Design, chronicles his fascinating journey from full-time employment to being self-employed at woodworking. Follow the riveting story of how his hi-tech career gradually evolved into a woodworking career. Read how Norman overcame obstacles and through determination and perseverance, finally attained his goal of self-employment at woodworking. Discover how Norman acquired the skills and techniques to be able to craft heirloom furniture today. Author Norman Pirollo shares his creative journey from childhood through adulthood. Perseverance, fate and critical decisions all combined to map out the direction he followed in life.

Looking back at his early youth, it can be seen that creativity was always his strong point. As the journey progressed, he often sought creative outlets and challenges in life. Woodworking ultimately became his creative outlet. Norman faced many obstacles throughout the journey and financial support was often at the forefront. He enjoys where he is today in life, having accumulated considerable experience and expertise at several woodworking businesses. He is also indebted to his former hi-tech career, which provided him fulfillment for a number of years. There were many false starts in transitioning from full time employment to being self-employed at woodworking. The opportunity to work at something he truly enjoys has ultimately brought solace and independence to his life.

Delving into and studying the history of furniture design has provided him the language and background to develop his own contemporary styled furniture. Read how he immersed himself into the contemporary furniture world to develop a style and voice of his own. Find out how, through twists and turns, Norman acquired the expertise and proficiency to become an award-winning furniture maker. Norman never looks back at missed opportunities. It is also important to view any setbacks as valuable experience in your own journey. The time and effort invested in following your own dream will be well worth it.

Norman also maintains a blog of ongoing projects in his studio at: pirollodesign.com as well as having recently written and published three books. Books and magazines featuring the authors furniture, work methods and philosophy:

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (New Art Press)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer Publishing)

IDS15 (Studio North)

IDS14 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014 IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking magazine

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer Books)

Fine Woodworking Shopmade Jigs 2009 2012

Canadian Interiors Design Source Guide

Ottawa Life magazine

Panoram Italia magazine

Our Homes magazine

Craft Journal

“Norman, I just finished your book!!! What a journey you have traveled to arrive at your present creative self. Your art speaks for itself but I really identified with your business approach to developing your brand. A really good read” Carole Malcolm, fine artist at www.carolemalcolm.com

230 Pages, Non-fiction, Softcover.

Digital version available ($15) at WoodSkills

Print version of book $19 available directly at Amazon

Cabinet build…

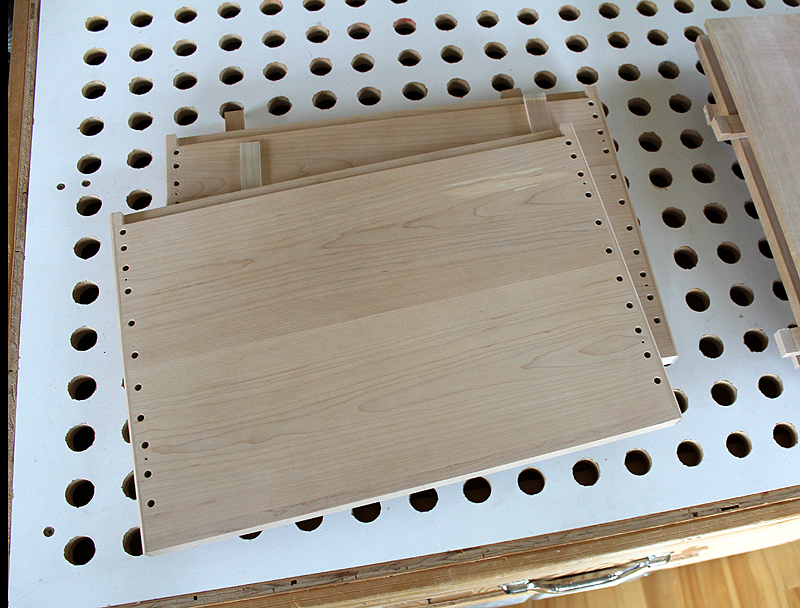

I’ve been working on the components for a standalone cabinet lately. As well, working on the design of a second smaller cabinet with a unique focal point, to be discussed later. The cabinet on stand below features one of my favorite figured woods, domestic ambrosia maple. I have a small stash of this wood in planks so the decision was made to resaw the wide planks and create veneers. Veneers maximize the yield from the planks. The cabinet will have veneered front doors and side panels. The remainder of the cabinet, the top and bottom panels and back panel consist of conventional maple. Ambrosia maple, when finish is applied, exhibits a beautiful, warm color while accentuating the wild graphics it is renown for. The graphics are what draw me to ambrosia maple. Also, it is a member of the soft maple family, so not difficult to work with and to smooth the surfaces. One of the attached pics is an earlier cabinet I completed using ambrosia maple throughout.

I have yet to decide on the finish of the current cabinet build, definitely something that will highlight the wood graphics.The other pics are the almost completed panels I will be using in the build. The veneered panels are not exciting at this time, but application of a penetrating clear finish will pop the graphics, colors and grain. The frame and panel back is a work in progress at this time. The interior compartments will also be different but consist of dovetailed drawers in an unusual arrangement.

The dimensions in the current version will be close to that of the earlier version since the proportions appealed to me. I have not yet designed or created the components for the stand, so this might be different than the earlier version. What I typically do is build the cabinet, then begin work on the platform or stand. The process is not as overwhelming to me using this approach, as I prefer to work on a project in stages. The satisfaction of seeing tangible progress in the project motivates and excites me to continue 🙂 More details to follow on the individual components and joinery used.

The dimensions in the current version will be close to that of the earlier version since the proportions appealed to me. I have not yet designed or created the components for the stand, so this might be different than the earlier version. What I typically do is build the cabinet, then begin work on the platform or stand. The process is not as overwhelming to me using this approach, as I prefer to work on a project in stages. The satisfaction of seeing tangible progress in the project motivates and excites me to continue 🙂 More details to follow on the individual components and joinery used.

New Youtube channel…

I’ve been adding videos to my new YouTube Channel WoodSkills for a few weeks now. Through the channel, I hope to convey my methods of work as well as enlightenment in the use of hand tools in woodworking. In the most recent series, I describe a shop-made slot mortiser. On the topic of furniture design, good design is essential in a quality furniture piece. Good design also minimizes wasted resources and provides a furniture maker with essential feedback and pause when creating furniture. Loosely translated, the design process keeps the maker from rushing into a potentially flawed furniture design. The checks and balances give pause to the process as well as streamlining the build.

Other videos discuss hand planes,shooting boards and bench hooks. These are essential tools I use in my own workshop. Once familiar with these tools, your woodworking will arrive at the next level. Feel free to subscribe to the YouTube channel WoodSkills as I will be posting at least one new video per week. These past two weeks are the exception as I have been travelling. An overdue vacation in the Rocky Mountains of Canada 🙂

Other videos discuss hand planes,shooting boards and bench hooks. These are essential tools I use in my own workshop. Once familiar with these tools, your woodworking will arrive at the next level. Feel free to subscribe to the YouTube channel WoodSkills as I will be posting at least one new video per week. These past two weeks are the exception as I have been travelling. An overdue vacation in the Rocky Mountains of Canada 🙂

Woodworking: Design to Making

Decades of furniture making experience combine with furniture design in this new and refreshing take on woodworking. In addition to detailed furniture making techniques, the book delves into the thought process behind furniture design. Skills and processes to advance you as a woodworker and furniture maker are described. The book is also a window on the life of a furniture maker. Although the focus of the book is hand tools, use of machines in the preparatory phase of a furniture build is addressed. Time and labor-saving precision hand tool procedures are discussed. The emphasis turns to hand tools in latter stages of a furniture build where attention to detail is necessary. A reverence to wood as a medium is featured throughout the book.

Homage is paid to classic techniques such as dovetail joinery and workbench processes. As well as the traditional, modern techniques and processes are put forward to make your furniture designs stand out and be unique. The focus is one of a kind furniture, the unique furniture and wood objects that separate you from other makers. As a furniture designer + maker, discover my passion, what drives me and where I draw inspiration from. Learn how to develop your own style, aesthetic and voice in furniture design. It is not the how but the why behind the process that is often critical in a furniture maker’s mind and practice.

The premise for this book is to provide insight into the craft of woodworking and more specifically the creation of furniture. The book is composed of sections, each of which is critical to your woodworking journey. Acquiring skills and knowledge in the last century involved taking classes, reading books or mentoring with a knowledgeable woodworker. Today, in comparison, there is a wealth of knowledge available through the Internet. What is lacking however, is the hands on aspect of the craft of woodworking. Learning involves making. I know of no one that learned a craft by simply reading and not applying themselves. It is critical to embrace the often lengthy learning curve involved. This book includes several articles focusing on woodworking in a contemporary world.

The book is composed of four sections. Each section contains articles that a woodworker or furniture maker will need to embrace as they evolve. The first section introduces basic woodworking skills. A large part of this book is devoted to hand tool skills. Although machines are combined with hand tools in my furniture making, I advocate that woodworkers should embrace hand tools. It is necessary to form a connection between hand and wood medium prior to seeking efficiency and a production mindset. Hand tools often get a bad rap as being slow and tedious. Instead, what hand tools offer is control, dexterity, quiet and a close connection to the wood medium. In a one person furniture making studio, hand tools offer a healthy balance to the use of machines. Projects include through dovetails, portable board jack build, moxon vise build and knife hinge install.

The second or furniture maker section provides a glimpse into furniture making as a career. Woodworkers often aspire to become furniture makers or go into business for themselves. As a furniture maker for several decades, I share knowledge and insight acquired over the years. Some articles will inspire you to take the leap and become a full time furniture maker. Topics in the section include setting up shop, the furniture maker journey, the furniture maker lifestyle, social media for a furniture maker, and insight into diverging from furniture making to other forms of woodworking.

The third section is devoted to furniture design. Furniture design forms a large part of woodworking. Often, it is necessary to design a complete piece of furniture or modify an existing design. The design process has evolved over past decades with the advent of computer software (CAD). Pencil and paper are now combined with CAD. Articles include how to create and refine a design, the concept of form and function and how it applies to furniture.

The fourth or advanced woodworking section delves into techniques to further your woodworking and furniture making. Veneering techniques, both manual and vacuum veneering are described. The process of creating a jewelry box is discussed in one article. The Japanese art of Kumiko is described in a final article.

Patrick Soran writes: “Beautiful book. Well done.”

235 Pages, 8.5 X 11 in. Non-fiction. $15

WOODWORKING: From Design To Making $15 (Digital)

Print Edition: WOODWORKING: FROM DESIGN TO MAKING $36.95

WOODSKILLS Issue 01

The semiannual woodworking magazine for the discerning, fine woodworking enthusiast. Digital magazine, also available in print. There is a small amount of curated advertising in the magazine consisting of products or services that fit with the mission of magazine. Published twice a year, WOODSKILLS magazine issues consist primarily of content. This issue features the following furniture makers: Jacques Breau (Canada), Alexandra Climent (NYC) and Philip Morley (Texas). Articles on the following subjects included in each issue.

Woodworker and Furniture Designer Profiles

Workshop Setups & Best Practices

Hand Tool Techniques

Furniture Design Gallery

Contemporary Furniture Design

Woodworking Tool Articles

WOODSKILLS Issue 01 Print Edition preview

Wayne Delyea Furniture Maker says “I bought the downloadable version of the magazine and I want to take time and let everyone know that I really liked it. Well written, informative, educational and thoughtful well executed photography made this well worth what I think is a very reasonable price. I Wish it was at least quarterly vs semiannual. Good job!”

Richard Garrow says “I received my copy yesterday and I must say it is very well written, very detailed, each story has a great content. The pictures look fantastic as well. I believe you going to publish this ones or twice a year is that correct? As look forward to your next issue.”

86 Pages (mostly content)

Digital version $10 USD

WOODSKILLS Issue 01 $10 (Digital)

WOODSKILLS Issue 01 (Amazon-Print) $17.95

WOODSKILLS Issue 01 (Premium-Print) $22.79

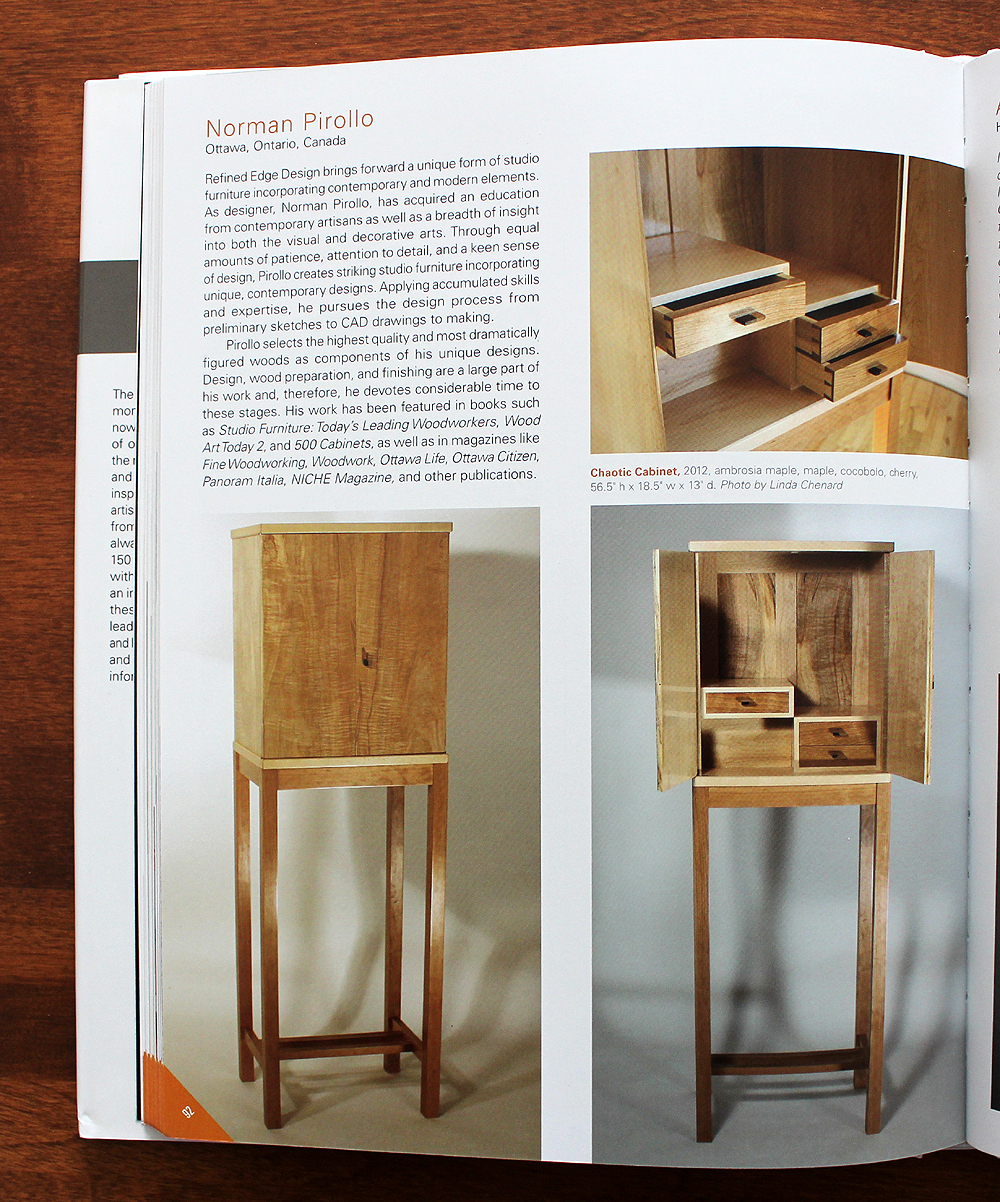

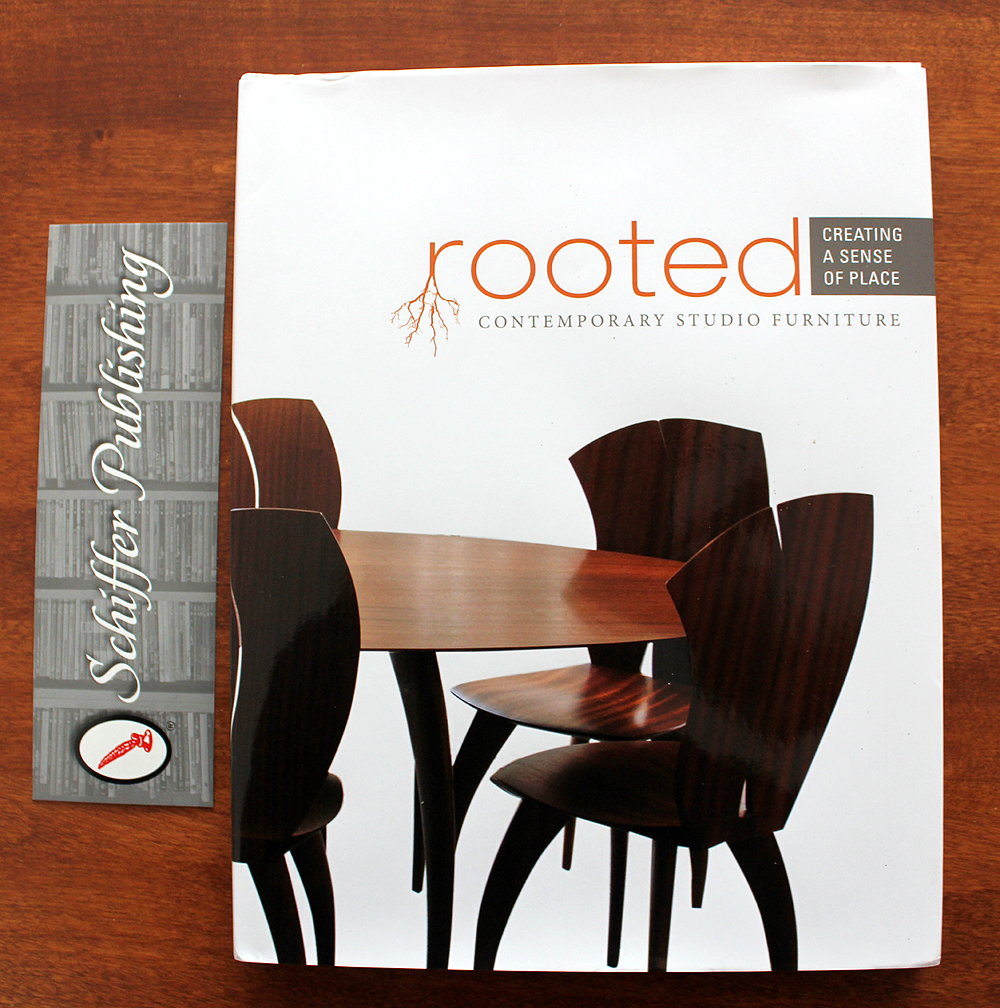

“Rooted” book has arrived…

A few months ago I was notified that my entry had been selected for an upcoming book on contemporary furniture. I finally managed to get hold of the book and received it this week.

The Schiffer publication: Rooted: Creating a Sense of Place: Contemporary Studio Furniture features a selection of contemporary furniture typically created in furniture studios by a single maker.

Quote from Amazon.com: “The movement to buy locally, which has gained momentum in the areas of produce and food, is now spreading to arts and crafts. Through the work of over seventy contemporary furniture makers, the role of place in the creative process is explored and celebrated. Whether in terms of materials, inspiration, or the interaction with customers, these artists are rooted in their surroundings. What springs from these roots is usually unique, often edgy, and always beautiful furniture and accessories.”

In a few weeks, I will post the Introduction to a series of videos on Furniture Design. Working and developing this project as we speak. It began as a small exercise but I’m adding material and more of my knowledge on furniture design principles to this topic.

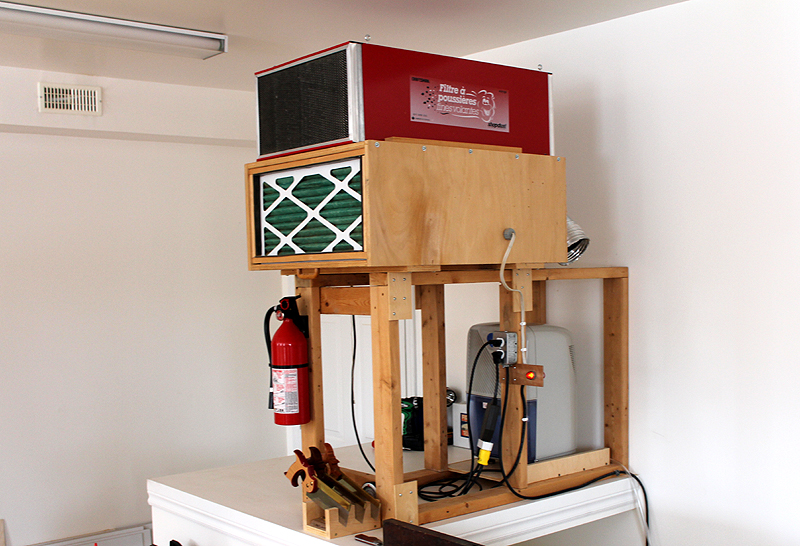

Clearing the air…

With the experience of my first workshop in mind, dust control became a priority for me when designing my new workshop. I recall not only sweeping the floors in my previous shop but also sweeping the walls of dust. The dust was the flavour of the day, be it walnut, padauk, cherry, mahogany. The dark, exotic woods were the worst for dust. I installed some dust collection but it was never enough. At the time, my woodworking was more oriented towards the use of sanding in the final stages of a build, so this didn’t help. The dust collection I installed was to capture the dust at the source or as it was being generated. This worked to a degree but there would always be airborne dust floating around, a by-product of whatever wood processing I was performing at the time. This is the dust that collects on walls, stays in the air and is unfortunately breathed in.

To combat this I built a 3-stage air cleaner as there were next to no commercial units available at the time or they were expensive. This helped considerably in capturing the airborne dust and I immediately became a believer in effective dust control. The shop made air cleaner can be seen here as well as a 3-stage commercial unit just above it. The shop made air cleaner is now moved into my new workshop and together these units effectively clean and circulate the air. Both units are stack-mounted in an unused part of the shop above a stairwell. The air in the shop is recirculated from top to bottom many times per hour and in the process scrubbing the air of fine particulate dust. I use these air cleaners in conjunction with two large capacity DC systems with blast gates at each of the stationary machines in the workshop. So dust control is an important part of my woodworking now. My woodworking today also places much less emphasis on sanding and instead I use hand tools to smooth surfaces of wood.

The air cleaners are turned on using a hand-held remote control. The most recent addition is the large red neon pilot lamp which indicates that the air cleaners are running. When I am using a machine, it is difficult to tell if the air cleaners have been turned on since the machine noise exceeds that of the air cleaners. The newly-installed red pilot lamp is immediately noticeable. The air cleaners also have ducting at the rear to direct air downwards to create the recirculating pattern for the shop air.

Wood offcuts (save or burn)…

Not the most exciting blog post but I finally got around to cleaning out the piles and piles of offcuts I had been storing throughout my workshop. What brought this about is I literally had run out of space, piles were brimming with wood offcuts of every size. It gets to a point where it doesn’t make sense to keep collecting the wood, I’ll only generate more anyway! So how to go about this task since the most difficult thing is parting with an offcut that might be of use in a future project as this is instilled in us as woodworkers. As we all know, hardwoods have become expensive so the offcuts become more precious as time goes on. After all, they have already been processed, planed, squared, etc. Pics reflect the post-tidying, uncluttered look.

I began by tackling two large grey bins that were literally overflowing. I could not place one more scrap piece in them. The laborious task of sifting through them began. It was much like an archaeological dig of past projects. Each layer reminded me of an earlier project and once I got to the bottom I could see some of my earlier work. I moved the larger pieces to two large cardboard boxes to be stored away in a completely different part of the building. The remainder I intend to use as fireplace kindling. Once I got through the first grey bin, the second one was easy. I conditioned myself to be discriminating and if I thought the offcut was not worth saving, it would become kindling. It has been at least 3 years since these bins have been completely emptied.

Next were 3 other wood piles that had grown to an unwieldy size. One pile in particular beneath my vacuum pump had become an eyesore. This had to get sorted out. I recently purchased a new shop vac and the box it came in was a large enough size for these longer offcuts. Next issue was where to place the box. If I kept it in plain view I would have accomplished nothing except move wood offcuts from one pile to another. I needed to find an unused space, preferably out of sight. The space behind a dust collector was not used and just the right size. The large box of offcuts was also placed on a small dolly with casters I had lying around. Now I can conveniently access these longer offcuts and if necessary easily move the box to a different location.

With this all done, I tackled the shelves under two of my larger workbenches below. It is so true what they say that these shelves eventually become storage for anything and everything. By now I was merciless, I wanted clean surfaces free of clutter. This exercise also provided me the opportunity to get re-acquainted with some buried tools and hardware 🙂

With this all done, I tackled the shelves under two of my larger workbenches below. It is so true what they say that these shelves eventually become storage for anything and everything. By now I was merciless, I wanted clean surfaces free of clutter. This exercise also provided me the opportunity to get re-acquainted with some buried tools and hardware 🙂

The last task was to clean the tops of the two smaller, identical workbenches below. In one case, the workbench top had not been cleaned in maybe 3 years. Everything was removed from each of the two workbench tops and put back in its place, be it drawers or cabinets. From now on I will work hard at leaving workbench surfaces free of clutter and deal with offcuts as I work through a project. After all, I have enough offcuts already to last a lifetime. Will I ever use them all, probably not. Maybe donate them to woodworkers that create smaller objects?

Last but not least is a large beast of a workbench I made years ago (seen below). I had moved this workbench to an area of the lower level workshop and it has slowly become a storage area with occasional use as a workbench. I need to tackle this area next and cull some of the wood, tools and hardware accumulated over the years. I have always enjoyed using this workbench and want to make it available once again. So I will be cleaning and tidying up this area up tomorrow with the intent to have a usable workbench once again.

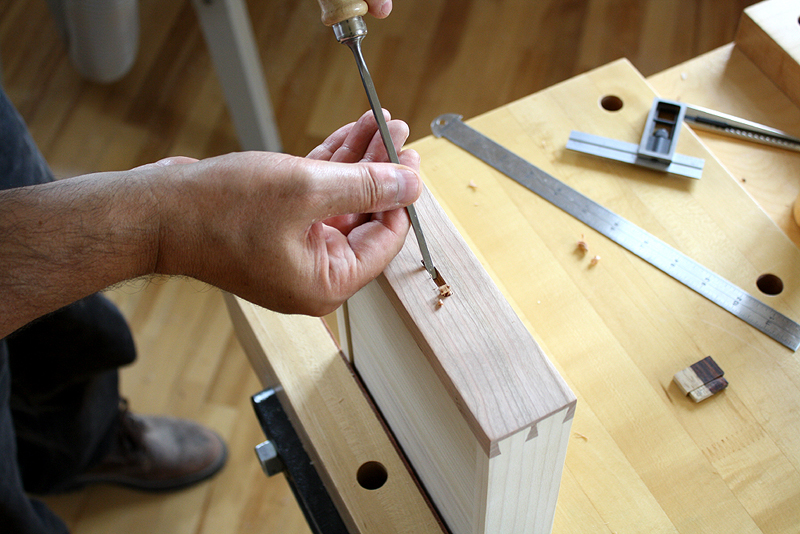

Drawer pulls…

My process for creating and fitting drawer pulls is outlined here. This involves designing the pulls, selecting the preferred wood to use for the pulls, deciding on a size for the pulls, laying out the pulls, and shaping them. I need to admit this is one of my most enjoyable processes of a build. The build is at its final stages and this can be considered the “adding the icing” part. Pulls often add considerably to a cabinet both in aesthetics and design. The pulls are often a draw to the cabinet if they complement the cabinet yet impart a unique addition to the cabinet. In these photos, the pull design I is a rectangular one with a tenon extending out. The pulls are of mixed cocobolo so both heartwood and sapwood create an appealing contrast in colors. The tenon has shoulders on four sides to overlay the drawer front. This tenon fits into a matching mortise in the drawer front. The mortise is marked and created using hand tools, namely small, narrow chisels.

Creating the tenon is meticulous work and I used a small, fine saw to delineate the tenon from the actual pull area. Once this is done, I use a skew rabbet block plane and some small chisels to shape the sides of the tenon. The important part of this sequence is to accurately mark the mortise to fit the tenon. A mistake here could ruin the drawer front or involve a re-design of the pulls to correct the error. The tenons of the drawer pulls fit tightly into the mortise and then glued in. I also take some time to orient the drawer pull graphics and orientation to match each other.

After completing and installing the drawers pulls I proceed to adding a pull to the right door of this particular cabinet. This door pull is similar to the drawer pulls to maintain harmony in the design. This design involves one pull on this door to distinguish this door as the one to open first. I’ve always liked the idea of having a single pull on the cabinet front, it just looks like a clean, minimalist design. This door pull is also slightly offset towards the bottom of the door to minimize any impact it might have on the door graphics as more of the door graphics are now visible above the door pull.

Slot mortiser (a new life)…

Tech in wood joinery meets handcrafted design + build. Top is a mortising unit, below is a micro-adjust created using traditional methods. The story follows. I purchased this Jessem Mortise Mill unit a few years back and although I managed to produce some loose tenon slots successfully, it was not easy to set up. I can’t recall the issues exactly, but I was frustrated at times. So recently found the unit buried under a secondary workbench and decided I would make an effort at getting it to work successfully. I had always wanted a horizontal slot mortiser setup and thought why not set this up to create slots in the horizontal plane instead of the vertical plane. The unit was marketed to be installed vertically with board placement underneath. Notice the etchings on the Mill are upside down. I’m not sure if having boards hang below the unit contributed to the issues I had at the time, but nonetheless I wanted to mount it so loose tenon slots were created horizontally. First pic is before building the micro-adjust unit.

Next step was to find a suitable platform, i.e. workbench surface to be able to mount it. A rolling cart in my workshop was ideal since I could wheel the unit away when not in use and the footprint of the Mortise Mill was not large. The rolling cart has large locking casters which do a good job of keeping the cart immobile. Installed it so the surface of the base plate was even with the surface of the cart, this took some time. I used large enough 1/4-20 bolts to maintain rigidity and keep it from shifting.

Tested it afterwards and I was pleased with the results. The later addition of a L-shaped wood bracket to support stiles while they were being mortised worked well. The ends of rails to be mortised were easily supported by the wood surface of the rolling cart. Further testing with clamping of boards provided me with a repeatable setup. I liked the fact that I could permanently leave the Mortise Mill bolted to the rolling cart.

The only small issue was the vertical adjustment of the slots on a board. Since the Mortise Mill was installed horizontally, the adjustment was not as smooth as I would like due to the weight of the sliding component of the unit. I decided to make a micro-adjust setup to alleviate the problem using some scrap walnut and maple. As can be seen in the pics, it is all wood construction with a 1/2 inch lead screw and wood handle. The end of the lead screw has a custom cradle contoured to fit the bottom edge of the sliding part of the Mortise Mill. Now I can precisely dial-in slot placements!