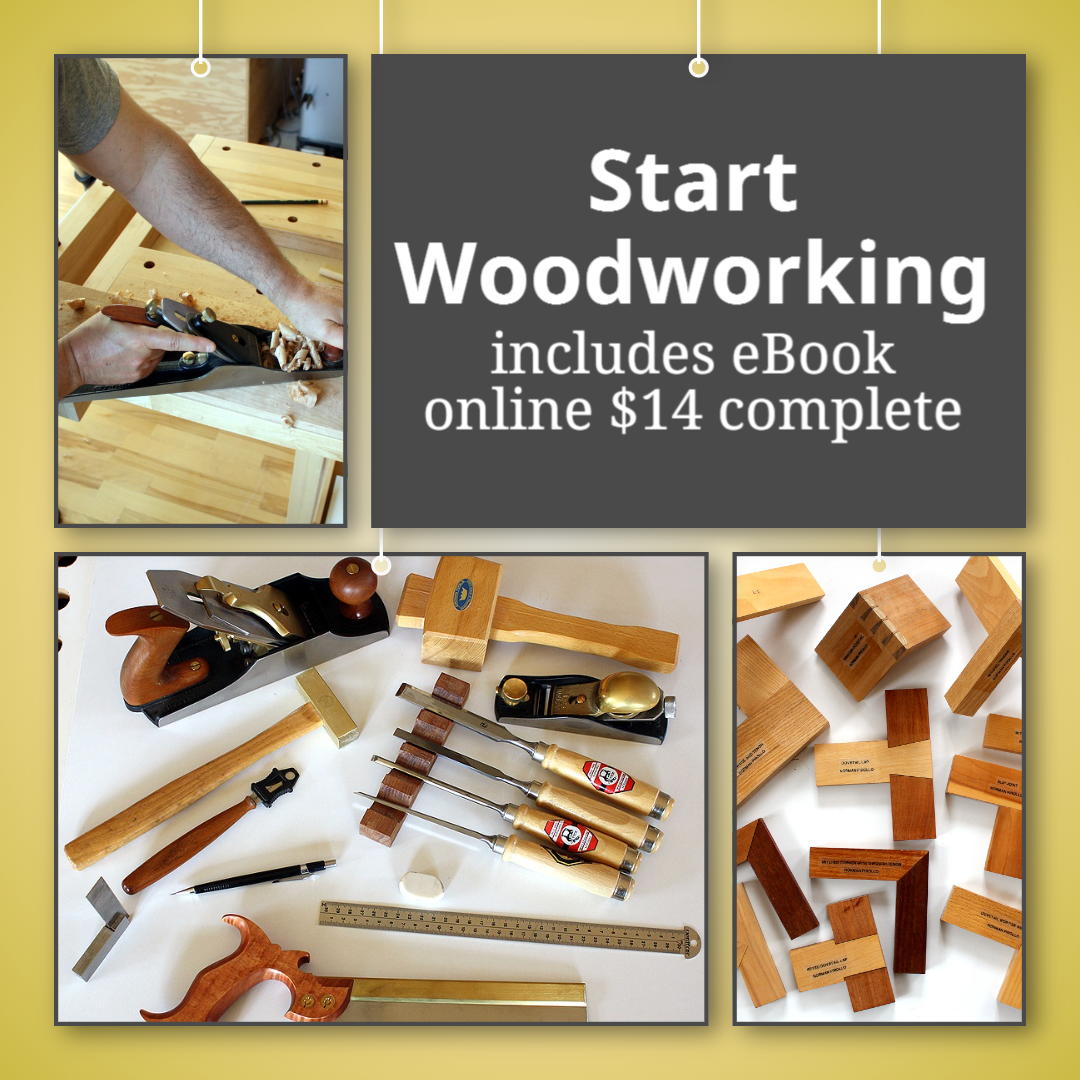

Start woodworking today! This eBook + videos (3) provide an introduction to woodworking and the tools necessary to begin woodworking. Woodworking is a broad subject but this eBook and videos explain the essentials. An inexpensive first set of tools is introduced and how to use them. Woodworking terminology is described along with important concepts to guide you through woodworking.

A relatively simple woodworking project is included. The project involves building a tool you will use in your future woodworking projects! Woodworking is an excellent outlet to channel your creativity. This Introductory course will motivate you to start your woodworking journey and build your first project!

After completing the eBook course, invest in the WoodSkills comprehensive Woodworking Course to further your woodworking education and continue your woodworking journey.

Norman maintains a blog of ongoing projects in his studio at Pirollo Design Blog as well as having written and published four books in the past year. Some of the books and magazines where authors furniture, work methods and philosophy have been featured:

Craftisian Interview (Norman Pirollo)

HackSpace Magazine – Make With Wood April 2020

Woodworking: From Design To Making (New Art Press)

The Wood Artist: Creating Art Through Wood (New Art Press)

From Hi-Tech to Lo-Tech: A Woodworker’s Journey (NAP)

Start Your Own Woodworking Business (New Art Press)

Rooted: Contemporary Studio Furniture (Schiffer)

IDS15 (Studio North)

Canadian Woodworking magazine Jan. 2015

Our Homes magazine Fall 2014

IDS14 (Studio North)

NICHE Magazine Winter 2013

Fine Woodworking Magazine 4 Bench Jigs for Handplanes

Fine Woodworking Magazine Essential Shopmade Jigs

Woodwork magazine

Wood Art Today 2 (Schiffer Books)

500 Cabinets ( Lark Books)

Studio Furniture: Today’s Leading Woodworkers (Schiffer)

Canadian Interiors Design Source Guide

Ottawa Life magazine (Profile,work) 2012

Panoram Italia magazine

Our Homes magazine

Also interesting are the dovetailed drawer fronts. I was striving for a wood tone not as dark as cherry and not light, just sufficient to provide some contrast to the maple. The wood originates from leftover European Beech offcuts used in a cabinet made in 2008 that was featured in the forward of the “500 Cabinets” book.

Also interesting are the dovetailed drawer fronts. I was striving for a wood tone not as dark as cherry and not light, just sufficient to provide some contrast to the maple. The wood originates from leftover European Beech offcuts used in a cabinet made in 2008 that was featured in the forward of the “500 Cabinets” book.