After completing and successfully testing the portable board jack in the previous post, I decided to continue on with workbench workholding accessories. At this point, two clamping attachments came to mind. The first, an edge dog, alternatively known as a bench puppy, was modelled after a College Of The Redwoods derived design. This particular design was gained from a Timothy Coleman article on this type of workholding device, also derived from a College Of The Redwoods design.

The premise of the edge dog is to use both the edge of a workbench top and one dog hole to hold a board on edge. This is performed through a unique design that hangs off the edge of the workbench top. When used in conjunction with a tail-vise, the edge dog excels at clamping the free end of a long or wide board along the edge of a workbench for jointing or other bench operations.

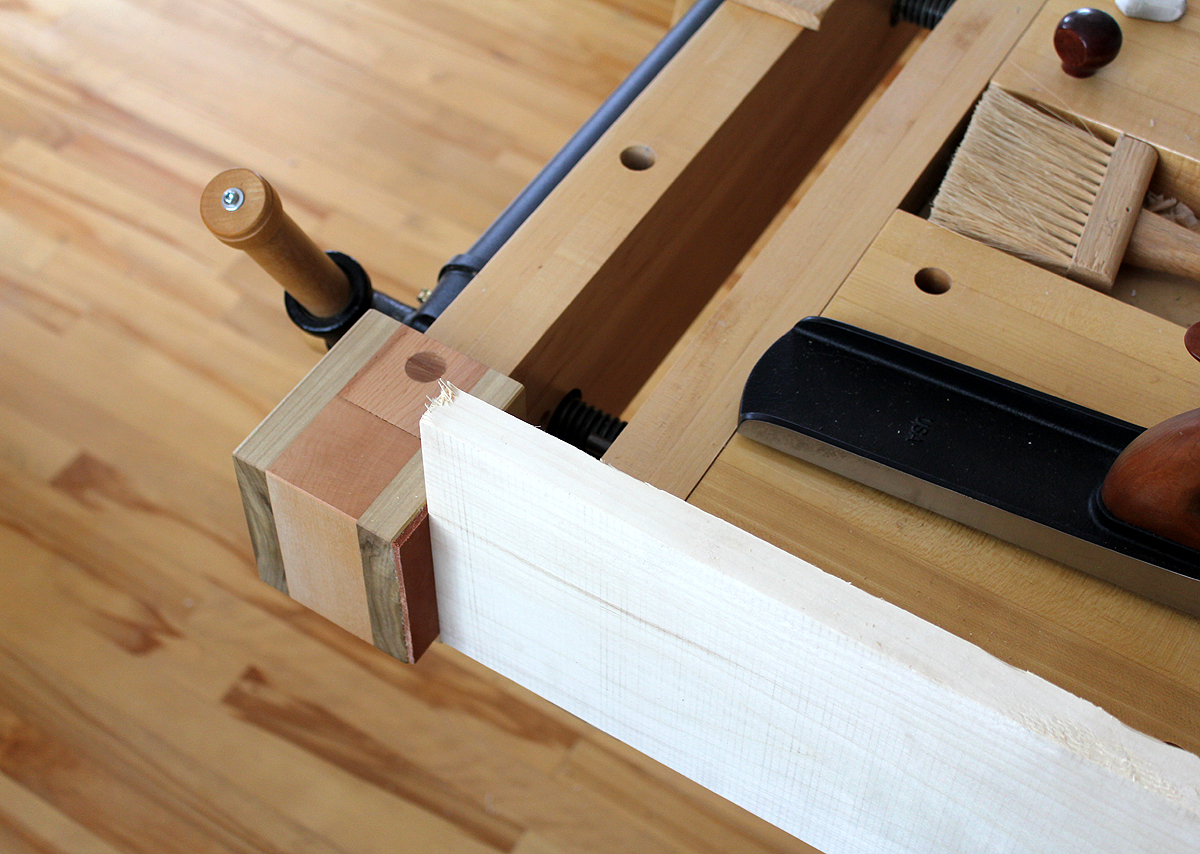

The edge dogs are customized to the spacing of the dog holes on a workbench, this would be the distance from the edge of the workbench to the leading row of dog holes. The measurement I refer to can be seen in the following images. I applied a leather face to the edge dogs and also drove a reinforcing wedge into the 3/4 in. dowel. The edge dogs are a combination of beech and maple, essentially what I had lying around in these dimensions.

A good example of how an edge dog can be used to hold a board on edge can be seen in the following image. One end is held by a edge dog whereas the other end is an add-on to a twin-screw vise which I discuss next. Instead of clamping a board to the surface of a workbench, the edge dog is used to clamp the board along the workbench edge and therefore at a more reasonable and lower height suitable for handplaning. Having a pair of these edge dogs allows either side of the workbench to be used. The edge dogs are created with opposing configurations as shown above.

A good example of how an edge dog can be used to hold a board on edge can be seen in the following image. One end is held by a edge dog whereas the other end is an add-on to a twin-screw vise which I discuss next. Instead of clamping a board to the surface of a workbench, the edge dog is used to clamp the board along the workbench edge and therefore at a more reasonable and lower height suitable for handplaning. Having a pair of these edge dogs allows either side of the workbench to be used. The edge dogs are created with opposing configurations as shown above.

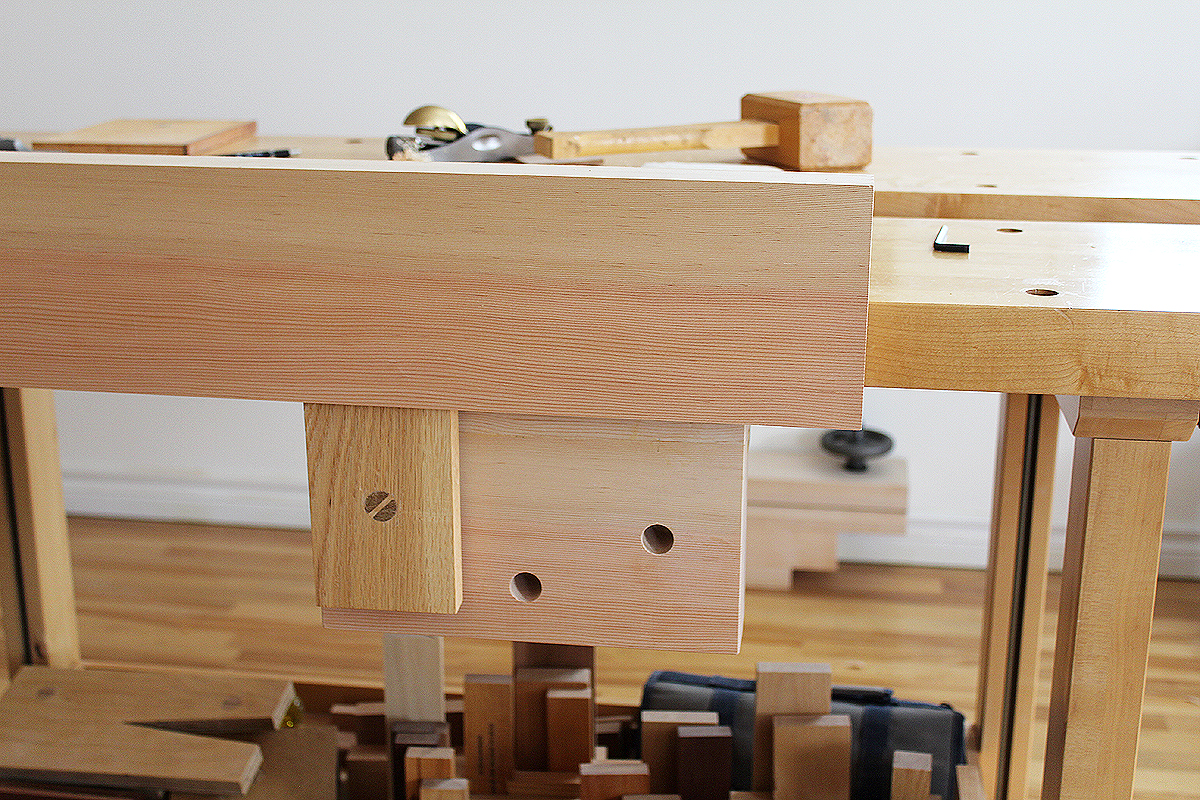

My current workbenches do not incorporate dedicated tail vises. In place, I use a Veritas Twin-screw vise which performs as a tail vise when clamping boards on their face. When it comes to clamping boards on edge, the twin-screw vise can also be used along with bench dogs. The edge of the workpiece would be then sitting on the workbench top. However, this raises the height of the board considerably and is not very conducive to handplaning or jointing an edge of a board. Ideally, the edge of a board should be slightly higher than the workbench surface to effectively perform handplane operations. With this in mind, I created this outboard add-on to the twin-screw vise which extends the width of the vise movable jaw past the edge of the workbench.

My current workbenches do not incorporate dedicated tail vises. In place, I use a Veritas Twin-screw vise which performs as a tail vise when clamping boards on their face. When it comes to clamping boards on edge, the twin-screw vise can also be used along with bench dogs. The edge of the workpiece would be then sitting on the workbench top. However, this raises the height of the board considerably and is not very conducive to handplaning or jointing an edge of a board. Ideally, the edge of a board should be slightly higher than the workbench surface to effectively perform handplane operations. With this in mind, I created this outboard add-on to the twin-screw vise which extends the width of the vise movable jaw past the edge of the workbench.

Shown above, this newly designed outboard add-on accessory is an addition to the twin-screw movable jaw. In effect, the vise now becomes an enhanced tail vise capable of clamping boards on edge along the side of a workbench. The clamping is done in conjunction with the previously mentioned edge dog. Images of a board being clamped between these two accessories are shown below.

Shown above, this newly designed outboard add-on accessory is an addition to the twin-screw movable jaw. In effect, the vise now becomes an enhanced tail vise capable of clamping boards on edge along the side of a workbench. The clamping is done in conjunction with the previously mentioned edge dog. Images of a board being clamped between these two accessories are shown below.

In these photos I am jointing the edge of a white ash board. I was surprised at how tightly the board is clamped with minimal tension applied to the twin screw vise. The friction from the leather pads contribute to this as slightly more tension was necessary before applying the leather pads. The outboard extension to the twin-screw vise is removable and can be adapted to either side of the twin-screw vise. I am left-handed so having it located to the right of the vise as shown, is more practical. For right-handed use, the opposite edge of the workbench would be used for jointing. As an added bonus, there is no racking of the twin-screw vise regardless of the clamping pressure I apply to the outboard extension.

In these photos I am jointing the edge of a white ash board. I was surprised at how tightly the board is clamped with minimal tension applied to the twin screw vise. The friction from the leather pads contribute to this as slightly more tension was necessary before applying the leather pads. The outboard extension to the twin-screw vise is removable and can be adapted to either side of the twin-screw vise. I am left-handed so having it located to the right of the vise as shown, is more practical. For right-handed use, the opposite edge of the workbench would be used for jointing. As an added bonus, there is no racking of the twin-screw vise regardless of the clamping pressure I apply to the outboard extension.

After a period of testing, I was pleasantly surprised at how well it works. It is completely unobtrusive and designed to accept standard 3/4 inch or 20 mm accessories such as surface clamps, bench dogs and shop-made planing stops. The portable board jack can be adapted to any slab-type workbench top without an existing apron or skirt as can be seen in the images. A face vise at one end keeps the board securely clamped on edge. Jointing the edge of long boards has become so much easier and second nature to me now.

After a period of testing, I was pleasantly surprised at how well it works. It is completely unobtrusive and designed to accept standard 3/4 inch or 20 mm accessories such as surface clamps, bench dogs and shop-made planing stops. The portable board jack can be adapted to any slab-type workbench top without an existing apron or skirt as can be seen in the images. A face vise at one end keeps the board securely clamped on edge. Jointing the edge of long boards has become so much easier and second nature to me now. The hole arrangement on the portable board jack is optimized for the work I do but can be modified if necessary. I no longer give any thought to attaching or clamping a long board on edge and along its length to my workbenches. Often, I simply need a peg to be able to rest the free end of a board on. This allows me to quickly and easily flip the board around to work both long edges.

The hole arrangement on the portable board jack is optimized for the work I do but can be modified if necessary. I no longer give any thought to attaching or clamping a long board on edge and along its length to my workbenches. Often, I simply need a peg to be able to rest the free end of a board on. This allows me to quickly and easily flip the board around to work both long edges. Now, I just selected my most-often used side of a workbench to work on and leave the portable board jack attached. In the future, I will possibly be creating another board jack for my other, similar workbench. This adds to the versatility since it will no longer be necessary to move the board jack from bench to bench.

Now, I just selected my most-often used side of a workbench to work on and leave the portable board jack attached. In the future, I will possibly be creating another board jack for my other, similar workbench. This adds to the versatility since it will no longer be necessary to move the board jack from bench to bench. Next up in the forthcoming installment or Part 2, a couple of cool bench accessories that continue with the theme of attaching and clamping long boards to a workbench. These are boards that are too long to simply clamp to a face vise. It just makes it so much more pleasant to perform handplaning or hand tool tasks once a board or panel is securely clamped. I like for this to be straightforward so I can focus on the task I need to perform instead of spending needless time on securely attaching and clamping a board to a workbench.

Next up in the forthcoming installment or Part 2, a couple of cool bench accessories that continue with the theme of attaching and clamping long boards to a workbench. These are boards that are too long to simply clamp to a face vise. It just makes it so much more pleasant to perform handplaning or hand tool tasks once a board or panel is securely clamped. I like for this to be straightforward so I can focus on the task I need to perform instead of spending needless time on securely attaching and clamping a board to a workbench.